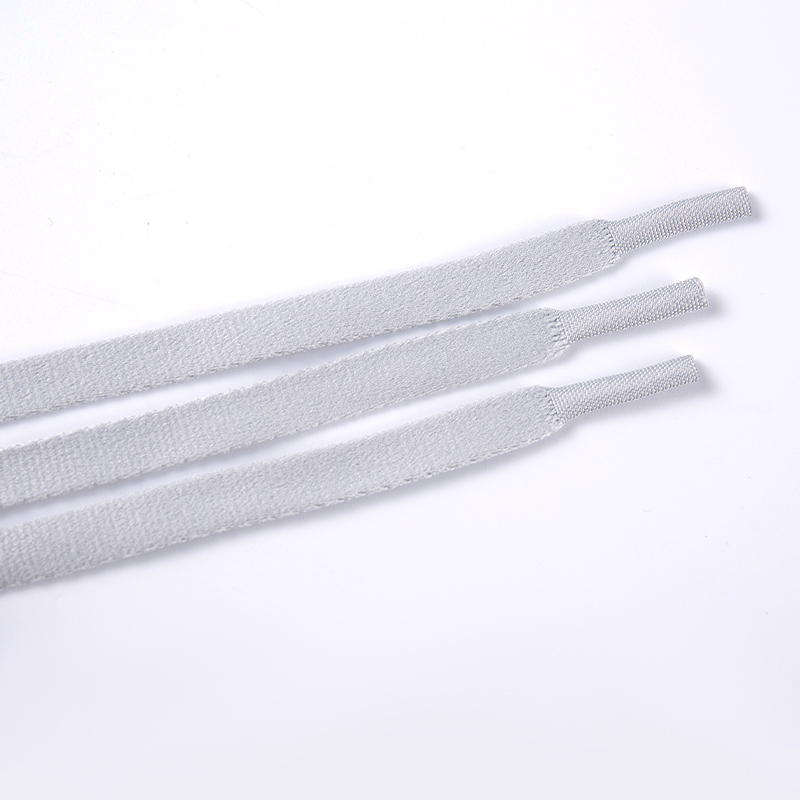

Cotton-hemp blend knit tapes, as a textile that combines the advantages of cotton fibers and linen fibers, have been widely favored in the market in recent years. Cotton fiber is known for its good hygroscopicity, breathability and soft feel, while flax fiber is known for its high strength, wear resistance, wrinkle resistance and good heat dissipation properties. The combination of the two aims to create a new textile material that is both comfortable and durable. However, the tensile strength of this blended material is not simply the sum of the strengths of the two fibers, but is affected by a variety of complex factors.

First of all, fiber content is one of the key factors affecting the tensile strength of cotton-hemp blend knit tapes. The fiber content directly determines the proportion of each component in the blended material, which in turn affects the mechanical properties of the overall material. While keeping other conditions constant, increasing the content of flax fiber will generally increase the tensile strength of the blended belt, because flax fiber itself has higher breaking strength and lower elongation. However, too high a flax content may also cause the material to feel hard and affect the wearing comfort. Therefore, in actual production, it is necessary to reasonably adjust the ratio of cotton and linen fibers according to the specific needs of the product to achieve the best balance between mechanical properties and wearing experience.

Secondly, the tensile properties of the fiber itself have a direct impact on the strength of the blended belt. There are differences in tensile properties between cotton fiber and flax fiber. Cotton fiber has better elasticity and ductility, while flax fiber is relatively brittle and hard with small elongation. In a tensile test, the flax fiber may break first because it cannot withstand excessive deformation. At this time, the load originally borne by the flax fiber will be transferred to the remaining cotton fiber. This process not only tests the overall strength of the blended yarn, but also reflects the complexity of fiber-fiber interactions in the blended material. Therefore, improving the tensile properties of the fiber itself, such as enhancing the strength and toughness of the fiber through chemical modification or physical treatment, is an effective way to improve the tensile strength of blended belts.

Furthermore, the choice of blending ratio is also an important factor in determining the tensile strength of blended knitted belts. Blending ratio refers to the proportion of different types of fibers in blended yarn. Reasonable blending ratio design can ensure the tensile strength while taking into account the softness, breathability and wear resistance of the material. For example, by adjusting the cotton and linen blending ratio, the product's feel and wearing comfort can be optimized while meeting certain strength requirements. In addition, the adjustment of the blending ratio can also flexibly adjust product characteristics according to changes in market demand to meet the needs of different consumer groups.

In addition to the above factors, the production process, post-processing process and testing conditions of the blended yarn will also affect the tensile strength of the cotton-hemp blend knit tapes. Therefore, during the production and quality control process, each link needs to be strictly controlled to ensure the stability and consistency of product performance.

English

English 中文简体

中文简体